Cutting

Trumpf Trulaser 5040 – 24 kW (2)

- Installed: 2025

- Cutting Capability: up to 2.3″

- Bed Size: 6′ x 12′

- Liftmaster Compact Loading/Unloading

- EdgeLine Bevel

- Thick Sheet Cutting Package

Trumpf Trulaser 5040 – 8kW

- Installed: 2019

- Cutting Capability: up to 1.0″

- Bed Size: 6′ x 12′

- TruStore 1000 Storage

- Liftmaster Compact Loading/Unloading

- Unload Conveyor

Messer Element 400L Unitized

- Installed: 2024

- Cutting Capability: up to 3.0″

- Bed Size: 10′ x 24′

- 400 Amp

- 5th-Axis Bevel Head @ 52º

- Dual Shuttle Tables

Trumpf Trulaser Tube 7000 – 6kW

- Installed: 2024

- Cutting Capability: up to 0.55″, 10″ Round, 7.8″ Square

- Bed Size: 40′ Infeed/27′ Outfeed

- Profile Detection

- Seam & Tube Alignment

- Unload Conveyor

Hyd-Mech V25APC-120

- Installed: 2025

- Cutting Capability: 30″ x 25″

- Bed Size: 60′ Infeed/10′ Outfeed

- Miter: 60º Left, 60º Right

- 1.5″ x 21′ Blade

- 120″ Multi-Index Feed

Hyd-Mech M20A (2)

- Installed: 2004 & 2012

- Cutting Capability: 30″ x 20″

- Bed Size: 60′ Infeed/10′ Outfeed

- Miter: 30º to 90º

- 1.5″ x 20′-6″ Blade

- 36″ Multi-Index Feed

HAAS VF-6/50 CNC Vertical Mill

- Installed: 2017

- Cutting Capability: 64″ x 32″ x 30″

- 30HP @ 7500 RPM

- 30 + 1 ATC Tool Capacity

- 4th-Axis rotary table

Voortman VB630M Saw & VB1050 Drill

- Installed: 2018

- Cutting Capability: 44″ x 20″

- Bed Size: 60′ Infeed/60′ Outfeed

- Drill: 7/16″ to 1′-9/16″

- Miter: -45º to 90º & 90º to 60º

- 2.125″ x 31′ Blade

LAGUN LS-3280 Lathe

- Installed: 2025

- Cutting Capability: 30″ x 80″

- 25HP @ 1000 RPM

- 9″ Thru Spindle

- 24″ Chuck

HAAS ST-40 CNC Lathe

- Installed: 2019

- Cutting Capability: 25.5″ x 44″

- 40HP @ 2400 RPM

- 3.5″ Thru Spindle

- 15″ Chuck

Bending

Trumpf Trubend 5230 – 250-Ton

- Installed: 2020

- Bed Size: 167″ (145″ between frames)

- 6-Axis Back Gauge

- 2x Bend Aides

- Hydraulic Upper & Lower Tooling Clamps

Trumpf Trubend 5320 – 350-Ton

- Installed: 2024

- Bed Size: 167″ (145″ between frames)

- 6-Axis Back Gauge

- 2x Bend Aides & Parking Position

- Robot & Toolmaster Interface Equipped

Trumpf Trubend 7036 – 40 Ton

- Installed: 2021

- Bed Size: 40″ (36″ between frames)

- Hydraulic Tool Clamping

- 6-Axis Back Gauge

- Operator Controlled Bending

Storage

STOPA Automated Sheet System

- Installed: 2025

- Bed Size: 6.7″ x 1.25″

- 12 Towers with 287 Pallets

- 2x Load/Unload Carts

- 2x Unload Stations

- 5.5-Tons per Location

KASTO Unibloc Structural System

- Installed: 2025

- Bed Size: 30″ x 20″ ID Cradles

- Storage Locations: 184 (40′ material), 80 (20′-24′ material)

- 6.5-Tons per Location

- 28 Rows x 8-Tall Cradle Stacking

- 3x Dual Shuttles for Material Delivery

Delivery

Truck & Trailer for Steel Deliveries

- 2-Ton Ford Pickup

- 8′ x 24′ Flatbed Trailer

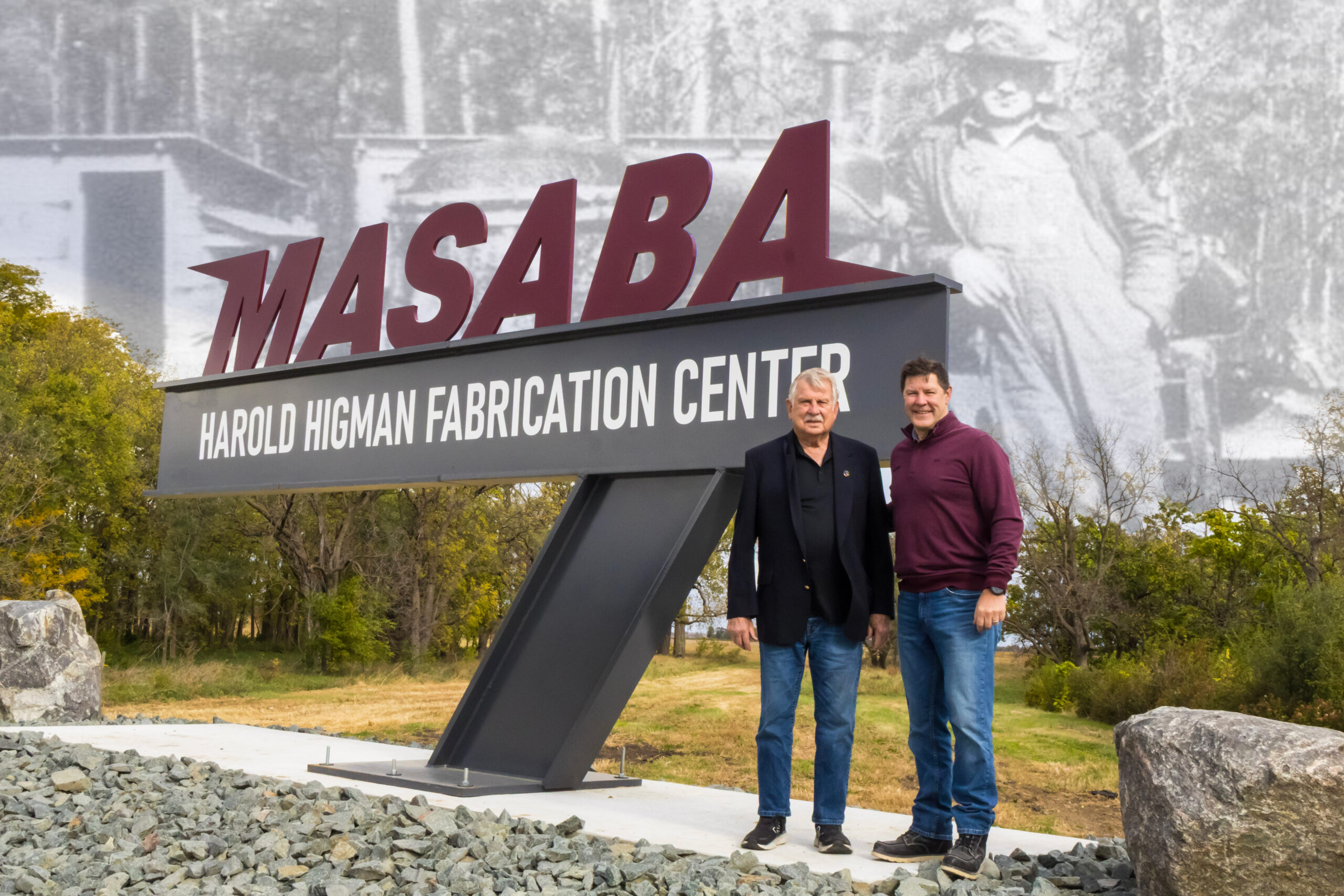

The Harold Higman Fabrication Center - 3 Generations of Grit

The Harold Higman Fabrication Center isn’t just a new facility — it’s a tribute to our roots. Named after Harold Higman Sr. and Jr., it honors their creativity, innovation, and the spirit that built Masaba.

This building now centralizes all fabrication processes — bending, cutting, and more — and its office space supports production, engineering, electrical operations, and metal sales.

At our original facility, we’ve added new welding and assembly bays in the former machine shop. Most office staff remain there, and we continue welding, assembly, and paint. With the new dedicated fabrication center and added space, our overall capacity has grown significantly.

Contact Us

Harold Higman Fabrication Center

1400 E 317th St.

Vermillion, SD 57069

Ken Karolevitz – Metal Sales

605-202-7020

metals@masabainc.com